概述

Introduction

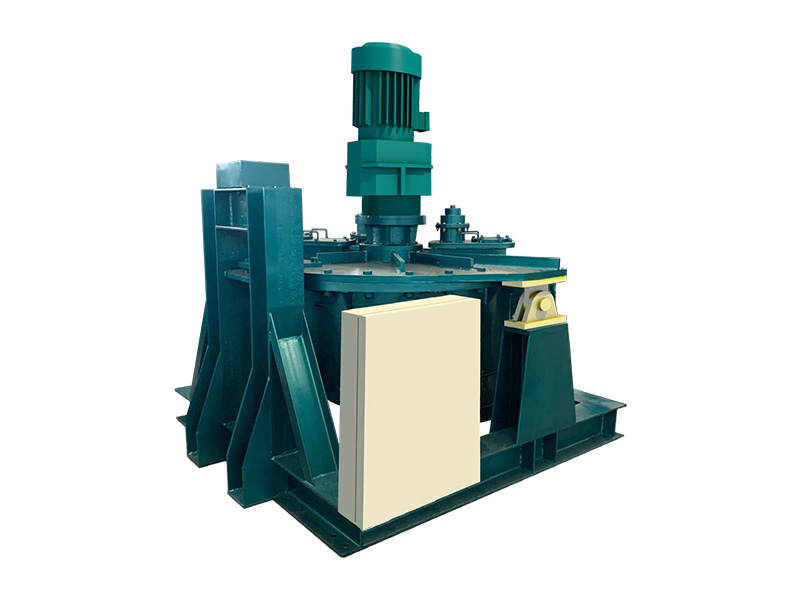

CWF分格转子定量喂煤装置把传统的煤粉定量喂煤、计量和锁风功能集成到一台装置中,专用于采用气力输送煤粉的定量喂煤。尤其适用于水泥、建材、冶金、电力等工业窑炉的定量喂煤。该装置荣获2011年度“华新杯”全国建材行业技术革新奖技术开发类二等奖;荣获中国建材机械工业品牌。

CWF Rotor Constant Coal Feeding Control Systemintegrates the functions of traditional constant coal feeding,metering and air locking into one device. lt's specially usedfor constant coal feeding by pneumatic conveying pulverizedcoal. lt is especially suitable for constant coal feeding ofindustrial kilns in cement,building materials, metallurgy andpower industries.The device was awarded the second prize intechnical development of 2011“Huaxin Cup”China NationalBuilding Materials Industry Technical Innovation Award and washonorably named as“Top Brand Product"in Chinese BuildingMaterials Machinery Industry.

技术指标

Technical indexes

喂料能力 Feeding capacity :0.3th~42th

计量精度 Metering accuracy :≤±0.5%

控制精度 Control accuracy :≤±1.0%

调节范围 Adjusting range :1:10

系统特点

Characteristics

1.直接测量转子内的煤粉重量,计量精度不受气流、物料特性的影响,计量稳定,运行可靠。

2.与送煤罗茨风机是一个整体,省去了螺旋泵等锁风装置。罗茨风机的压力变化不影响喂煤量和计量精度,有利于稳定窑的热工制度,延长窑砖的使用寿命,降低能耗,提高熟料质量。

3.采用重力下料结合压缩空气喷吹、负压抽吸助卸技术(发明专利,专利号:ZL201510658840.1),可有效地消除仓压的影响,防止冲料。空气喷吹装置可防止煤粉架桥、堵塞,使煤粉始终处于松散状态,保持一定密度。

4.实行了前馈控制技术,将任何时刻的转子负荷及其所处角位移存储在控制系统中,在煤粉卸出前,已知转子的负荷,由系统的设定流量值和转子负荷计算出卸料时的角速度,控制变频调速电机的速率,实现定量喂煤。

5.转子、密封板、出料头采用特种合金,确保设备使用寿命。

6.把传统的煤粉定量喂煤、计量和锁风功能集成到一台装置中,结构紧凑,占空间小,减少了基建投资。机械结构精致简单,维护方便,不需要专门工具和起重设备。

1. lt directly measures material weight inside the rotor,whose metering accuracy is accurate and will not be influencedby material property, air flow and material flow properties.

2.The device and the coal-conveying Roots fan weoffered is the whole system which leaves out the air-lock devicesuch as the screw pump. The pressure variation of Rootsfan will not influence the coal feeding amount and meteringaccuracy,which is good to stabilize the kiln thermal regulation,lengthen the refractory brick life,reduce energy consumptionand improve clinker quality.

3. lt combines discharging by gravity and injection bycompressed air (Invention patent, patent No. ZL201510658840.1), which couldeliminate effectively the influence of bin pressure and avoidmaterial surging. The air injection device could avoid pulverizedcoal arching and blockage to make the pulverized coal alwaysunder loose condition, with a certain density.

4. lt adopts the predictive control technology,whichsaves in the control system the rotor load and its angulardisplacement at any time. Before the pulverized coal isdischarged,the rotor load has been known.The angular speedduring material discharging is calculated on the basis of thesystem set flow rate and rotor load. In controlling the speedof frequency variable motor, we can realize quantitative coalfeeding.

5. Special alloy is used for rotor,sealing plate anddischarging head to ensure the equipment service life.

6. The three functions such as pulverized coalquantitative feeding, metering and air locking are integratedin one. It is characterized with compact structure and smallspace, thus reducing infrastructure investment.The mechanicalstructure is simple, with easy maintenance, which doesn't needspecial tools or hoisting device.

| 规格型号 Specification and model |

给料能力(m3/h) Feeding capacity |

稳定最大产量(㎡3/h) Stable maximum capacity |

整机重量(kg) Total weight |

||

|

正常工况产量 Capacity of normal working condition |

镍铁线输送距离 100m以上产量 capacity of ferronickel production line with conveying distance over 100m |

||||

| CWF800-125 | A型 | 8 | 6 | 4 | 3000 |

| B型 | 10 | 8 | 6 | ||

| CWF1000-160 | A型 | 16 | 12 | 9 | 4400 |

| B型 | 20 | 15 | 12 | ||

| CWF1200-200 | A型 | 32 | 24 | 19 | 5400 |

| B型 | 40 | 30 | 24 | ||

| CWF1400-300 | A型 | 70 | 52 | 41 | 8800 |

| B型 | 80 | 60 | 48 | ||

| CWF1400-330 | A型 | 100 | 75 | 60 | 9200 |

| B型 | 120 | 90 | 72 | ||

产品应用领域

Introduction

主要用于建材、冶金、电力、有色、化工等行业工业窑炉的定量喂煤。也可用于其它粉状燃料的定量喂料,如石油焦粉等。

1.建材行业,水泥生产回转窑、分解炉定量喂煤。

2.有色冶金行业,氧化铝、氧化镁、氧化锌等焙烧回转窑定量喂煤。

3.黑色冶金行业,球团矿回转窑、贫铁矿磁化焙烧回转窑、镍铁冶炼回转窑等定量喂煤。

4.化工行业,苏打、磷肥、硫化钡等煅烧回转窑定量喂煤。

5.余热发电锅炉定量喂煤

6.耐火材料生产原料煅烧回转窑定量喂煤。

7.其它行业,如:石灰、碳素、陶砂等窑炉定量喂煤。

Mainly suitable for constant coal feeding of industrial kilnsin building 'materials,metallurgy, power,nonferrous metal andchemical industries,also for constant coal feeding of otherpowdery fuels such as petroleum coke powder.

1. Constant coal feeding of the rotary kiln and calciner forcement production in the building material industry.

2. Constant coal feeding of rotary kilns for aluminumoxide,magnesium oxide and zinc oxide burning in the non-ferrous metallurgy industry.

3. Constant coal feeding of rotary kilns for pellet,leaniron ore magnetization burning and ferronickle smelting in theferrous metallurgy industry.

4. Constant coal feeding of rotary kilns for soda,phosphate fertilizer and barium sulfide burning in the chemicalindustry.

5.Constant coal feeding of waste heat power generationboilers.

6. Constant coal feeding of raw material burning rotarykiln for refractory material production.

7. Constant coal feeding of lime,carbon and fineceramsity kilns in other industries.

工艺方案

Technics Arrangement

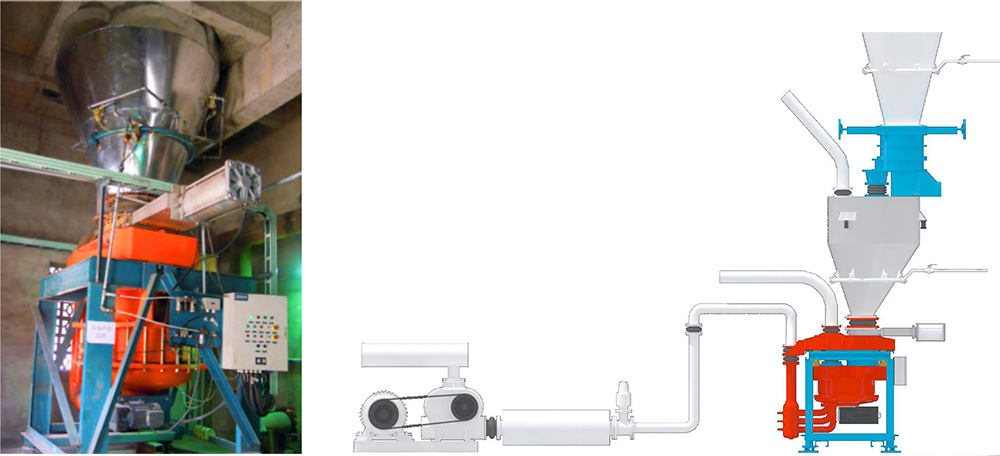

01-01 CWF/Y分格转子定量喂煤系统

CWFY Cellular Rotor Type Quantitative Coal Feeding System

CWF/Y型分格转子定量喂煤系统是把最新开发的分格转子定量喂煤装置与稳流下料管相结合组成的喂煤系统。

CWF/Y Cellular Rotor Type Quantitative Coal FeedingSystem combines the newly-developed rotor constant coalfeeding device with the steady flow discharge Pipe.

01-02 CWF/R分格转子定量喂煤系统

CWF/R Cellular Rotor Type Quantitative Coal Feeding System

CWF/R型分格转子定量喂煤系统把最新开发的分格转子定量喂煤装置与具有知识产权的喂料机相结合组成的喂煤系统。

CWF/R Cellular Rotor Type Quantitative Coal Feeding System combines the newly-developed rotor constant coal feeding device with the feeder that has intellectual property rights.

系统特点

Characteristics

1.具有自主知识产权的多层煤粉喂料机,采用分级喂料技术,保证喂料均匀稳定,不产生因气压结拱现象。

2.使用稳流仓结构,内部能保证煤粉的流动性,形成漏斗效应。同时配合适当的保温和负压抽吸助卸技术(发明专利,专利号:ZL201510658840.1),完全能避免稳流仓煤粉结壁。

3.宽接口设计,不存在煤粉在接口处挂壁,结料。同时喂料机内有搅拌器,使物料充分流化,避免粘壁,消除物料死区,有利于下料顺畅。

4.稳流仓料位实时控制,可根据工厂的实际工艺要求,将稳流仓设定在合理的仓位,确保喂煤连续、稳定。同时,可定期进行实物标定、确保长期稳定计量精度。

1. The multi-layer pulverized coal feeder with independent intellectual property rights uses classified feeding technology to ensure stable and even feeding and avoid the arching phenomenon due to air pressure.

2. The steady flow bin structure is used to ensure pulverized coal fluidity within the bin, thus forming funnel effect, meanwhile wall sticking of pulverized coal in the steady flow bin can be avoided in combination with thermal insulation and negative pressure suction auxiliary discharge technology (nation patent).

3. Wide joint is designed to avoid wall sticking of pulverized coal. There is the blender in the feeder to make materials fully fluidized, avoid wall sticking and eliminate material dead area, thus helping discharge smoothly.

4. The material level of steady flow bin is controlled in real time according to the actual technological requirement for the plant. The steady flow bin is set at the proper bin level to ensure stable and continuous coal feeding. The material calibration is regularly made to ensure long-time stable metering accuracy.

产品咨询

如果您对我们的产品有任何兴趣,欢迎随时给我们留下您的意向信息

Copyright © 开云「中国内陆」官方网站 皖ICP备2022000611号-1 网站建设:中企动力 合肥 SEO标签

0551-63439417/63439328

0551-63439417/63439328

点击咨询

点击咨询